STAINLESS STEEL PRODUCTS

310S STAINLESS STEEL TUBE/PIPE

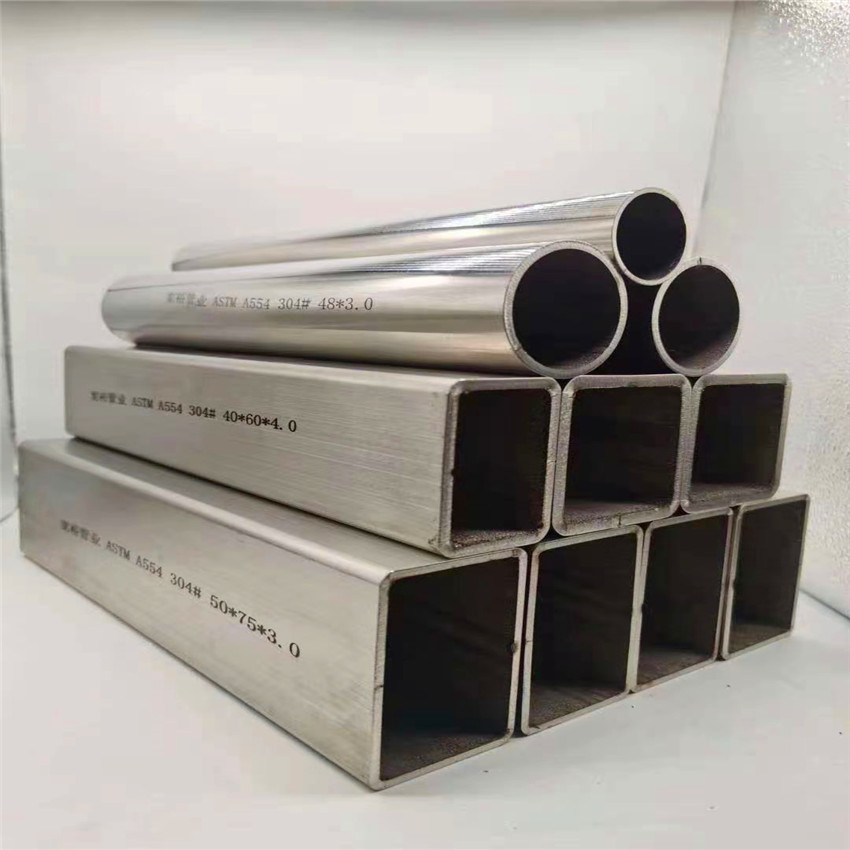

| ASTM 310S Stainless Steel Tube/Pipe | ||||||||

| Product: | ASTM 310S Stainless Steel Tube/Pipe | |||||||

| Material: | Stainless Steel 200 series,300series,400series | |||||||

| Standard: | ASTM/AISI/DIN/JIS/GB…. | |||||||

| Dimension: | Thickness:0.3MM-6MM,OD:8MM-325MM | |||||||

| Length: | Random Length | |||||||

| Surface Finish: | No.1/2B/No.4/4K/6K/8K/HL/Matt | |||||||

| Tchnology: | Cold Rolled ,Hot Rolled | |||||||

| MOQ: | 1TON | |||||||

| Package: | Standard Export Packing,Or As Per Your Requirement | |||||||

| Application: | Railings,Staircase Railing Balustrade,Windows,Balustrsde System,Equipment Manufacturing and Maintenance,etc. | |||||||

310S stainless steel tube:

Introduction:

310S stainless steel tube is a hollow long round steel, mainly used in petroleum, chemical, medical, food, light industry, mechanical instruments, etc. When the bending and torsional strength are the same, the weight is lighter, and it is widely used in manufacturing mechanical parts and engineering structures. Also commonly used as conventional weapons, barrels, shells, etc.

310s is an austenitic chromium-nickel stainless steel with good oxidation resistance and corrosion resistance. Because of a higher percentage of chromium and nickel, 310s has much better creep strength, can continue to operate at high temperatures, and has good high temperature resistance Sex.

Ingredient content:

310S (0Cr25Ni20/0Cr25Ni20Si2), heat-resistant stainless steel, domestic grade 0Cr25Ni20, American grade SA213/TP310S, commonly known as 310S, also known as 2520, duplex stainless steel, used for high temperature furnace tube manufacturing. The chemical composition of SA213/TP310S (%):

Ni Nickel: 19.00-22.00

Cr: 24.00-26.00

Si Silicon <= 1.50

Mn Manganese <= 2.00

C carbon <= 0.08

S sulfur <= 0.030

P phosphorus <= 0.035

The manufacturing method is basically the same as the seamless steel pipe. The steel used is in accordance with the rules of GB14975-94 “Stainless Steel Seamless Steel Pipe”. 1Cr23Ni18, 1Cr18Ni11Nb and other steel grades are made. Uses: stainless acid-resistant seamless steel tubes are widely used in petroleum, chemical industry, pipelines and various stainless steel, acid-resistant steel structural parts, should ensure the chemical composition and physical properties of steel.

Density: 8.0 g/cm3, mechanical properties after solution treatment: yield strength ≥205, tensile strength ≥520, elongation ≥40, hardness test: HBS≤187, HRB≤90, HV≤200

310S stainless steel is suitable for making various furnace components, the maximum working temperature is 1200 ℃, continuous use temperature is 1150 ℃.

310S stainless steel management theory weight calculation formula: (outer diameter-wall thickness)×wall thickness×0.02507=KG/M

Surface features:

The surface of 310s stainless steel pipe is divided into industrial surface and matte surface

A kind of 310s stainless steel tube with matte surface, only the surface has been matt treated. Otherwise, it is the same as the general 310s stainless steel pipe. The disposal method is as follows:

The matt liquid 1:1 is mixed with water to make the working liquid. At normal temperature or heating the electrolyte to 40-50 degrees, hang the lead plate or stainless steel plate on the cathode, fix the workpiece to be electrolytically polished on the anode, then adjust the voltage to about 5 volts, and remove the workpiece after 3-5 minutes of polishing. Complete matt electrolysis technology.

Technical process: chemical degreasing, derusting → water washing → electrolytic matt → water washing → neutralization → water washing → hot pure water washing

310s stainless steel pipe performance characteristics and application scope:

310s stainless steel pipe belongs to a kind of heat-resistant stainless steel, which is mainly used to manufacture high temperature furnace tubes. In addition, 310s stainless steel pipe has higher chromium and nickel content, and its corrosion resistance is better than 304 stainless steel pipe. In nitric acid with an azeotropic concentration above 68.4%, the conventional 304 stainless steel pipe does not have satisfactory corrosion resistance, while the 310s stainless steel pipe can be used in nitric acid with a concentration of 65-85%

The 310s stainless steel pipe has good thermal strength, vulcanization and vulcanization resistance. The use temperature is 1200 ℃, continuous use temperature is 1150 ℃, its heat resistance is much better than 304, 316, 321 stainless steel. Compared with nickel-chromium superalloy and cobalt-chromium superalloy, it has obvious cost advantages.

310s stainless steel pipe performance characteristics and application scope

310s stainless steel pipe belongs to a kind of heat-resistant stainless steel, which is mainly used to manufacture high temperature furnace tubes. In addition, 310s stainless steel pipe has higher chromium and nickel content, and its corrosion resistance is better than 304 stainless steel pipe. In nitric acid with an azeotropic concentration above 68.4%, the conventional 304 stainless steel pipe does not have satisfactory corrosion resistance, while the 310s stainless steel pipe can be used in nitric acid with a concentration of 65-85%

The 310s stainless steel pipe has good thermal strength, vulcanization and vulcanization resistance. The use temperature is 1200 ℃, continuous use temperature is 1150 ℃, its heat resistance is much better than 304, 316, 321 stainless steel. Compared with nickel-chromium superalloy and cobalt-chromium superalloy, it has obvious cost advantages.

| Mechanical Property | |||||

| ASTM | TS(Mpa)≥ | YS(Mpa)≥ | EL(%)≥ | Hardness | |

| HB | HRB | ||||

| 201 | 520 | 275 | 40 | 241 | 100 |

| 202 | 520 | 275 | 40 | 207 | 95 |

| 301 | 520 | 205 | 40 | 207 | 95 |

| 304 | 520 | 205 | 40 | 20 | 90 |

| 304L | 480 | 175 | 40 | 187 | 90 |

| 309S | 520 | 205 | 40 | 187 | 90 |

| 310 | 520 | 205 | 40 | 187 | 90 |

| 310S | 520 | 205 | 40 | 187 | 90 |

| 316 | 520 | 205 | 40 | 187 | 90 |

| 316L | 480 | 175 | 40 | 187 | 90 |

| 316Ti | 520 | 205 | 40 | 187 | 90 |

| 317L | 480 | 175 | 40 | 187 | 90 |

| 321 | 520 | 205 | 40 | 187 | 90 |

| 430 | 450 | 205 | 22 | 183 | 88 |

| 904L | 490 | 216 | 35 | ||

| 2205 | 640 | 25 | |||

| Chemical Composition | ||||||||||||

| Chemical Composition(%) | ||||||||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | Cu | N | Other | ||

| 1Cr17Mn6Mi5N | 201 | 0.15 | 1.00 | 5.5-5.7 | 0.06 | 0.03 | 3.3-3.5 | 16-18 | _ | _ | 0.05-0.25 | |

| 1Cr18Mn8Mi5N | 202 | 0.15 | 1.00 | 7.5-10 | 0.06 | 0.03 | 4.0-6.0 | 17-19 | _ | _ | 0.05-0.25 | |

| 1Cr18Mn8Mi5N | 301 | 0.15 | 1.00 | 2.00 | 0.07 | 0.03 | 6.0-8.0 | 16-18 | _ | _ | 0.10 | |

| 0Cr18Ni9 | 304 | 0.07 | 1.00 | 2.00 | 0.035 | 0.03 | 8.1-10.0 | 17-19 | _ | _ | _ | |

| 0Cr18Ni9 | 309S | 0.08 | 1.00 | 2.00 | 0.035 | 0.03 | 12.0-15.0 | 22-24 | _ | _ | _ | |

| 0Cr25Ni20 | 310S | 0.08 | 1.00 | 2.00 | 0.035 | 0.03 | 19.0-22.0 | 24-26 | _ | _ | _ | |

| 0Cr17Ni12Mo2 | 316 | 0.08 | 1.00 | 2.00 | 0.035 | 0.03 | 10.0-14.0 | 16-18.5 | 2.0-3.0 | _ | _ | |

| 00Cr17Ni14Mo2 | 316L | 0.08 | 1.00 | 2.00 | 0.035 | 0.03 | 12.0-15.0 | 16-18 | 2.0-3.0 | _ | _ | |

| 0Cr18Ni12Mo3Ti | 316Ti | 0.08 | 1.00 | 2.00 | 0.035 | 0.03 | 11.0-14.0 | 16-19 | 2.5-3.5 | _ | _ | Ti≥5C |

| 0Cr18Ni12Mo3Ti | 317L | 0.03 | 1.00 | 2.00 | 0.035 | 0.03 | 11.0-15.0 | 18-20 | 3.0-4.0 | _ | _ | |

| 1Cr18Ni9Ti | 321 | 0.12 | 1.00 | 2.00 | 0.035 | 0.03 | 8.0-11.0 | 17-19 | _ | _ | _ | Ti5C-0.70 |

| 1Cr12 | 430 | 0.12 | 1.00 | 2.00 | 0.035 | 0.03 | 0.60 | 16-18 | _ | _ | _ | |

| 00Cr20Ni25Mo4.5Cu | 904L | 0.02 | 1.00 | 2.00 | 0.035 | 0.03 | 23.0-28.0 | 19-23 | 4.0-5.0 | 1.0-2.0 | 0.14-0.20 | |

| 00Cr2Ni5Mo3N | 2205 | 0.03 | 1.00 | 2.00 | 0.035 | 0.02 | 4.5-6.5 | 21-23 | 2.5-3.5 | _ | _ | |

| Stainless steel national standard _ stainless steel implementation standard _ national stainless steel grade comparison table | ||||||||||

| No | China GB | Japan | United States | Korea | EU | India | Australia | Taiwan, China | ||

| Old grade | New grade(07.10) | JIS | ASTM | UNS | KS | BS EN | IS | IS | CNS | |

| Austenitic stainless steel | ||||||||||

| 1 | lCrl7Mn6Ni5N | 12Crl7Mn6Ni5N | SUS201 | 201 | S20100 | STS201 | 1.4372 | 10Crl7Mn6Ni4N20 | 201-2 | 201 |

| 2 | lCrl8Mn8NI5N | 12Crl8Mn9Ni5N | SUS202 | 202 | S20200 | STS202 | 1.4373 | - | 202 | |

| 3 | lCrl7Ni7 | 12Crl7Ni7 | SUS301 | 301 | S30100 | STS301 | 1.4319 | 10Crl7Ni7 | 301 | 301 |

| 4 | 0Crl8Ni9 | 06Crl9Nil0 | SUS304 | 304 | S30400 | STS304 | 1.4301 | 07Crl8Ni9 | 304 | 304 |

| 5 | 00Crl9Nil0 | 022Crl9Nil0 | SUS304L | 304L | S30403 | STS304L | 1.4306 | 02Crl8Nill | 304L | 304L |

| 6 | 0Crl9Ni9N | 06Crl9Nil0N | SUS304N1 | 304N | S30451 | STS304N1 | 1.4315 | - | 304N1 | 304N1 |

| 7 | 0Crl9Nil0NbN | 06Crl9Ni9NbN | SUS304N2 | XM21 | S30452 | STS304N2 | - | - | 304N2 | 304N2 |

| 8 | 00Crl8Nil0N | 022Crl9Nil0N | SUS304LN | 304LN | S30453 | STS304LN | - | - | 304LN | 304LN |

| 9 | lCrl8Nil2 | 10Crl8Nil2 | SUS305 | 305 | S30500 | STS305 | 1.4303 | - | 305 | 305 |

| 10 | 0Cr23Nil3 | 06Cr23Nil3 | SUS309S | 309S | S30908 | STS309S | 1.4833 | - | 309S | 309S |

| 11 | 0Cr25Ni20 | 06Cr25Ni20 | SUS310S | 310S | S31008 | STS310S | 1.4845 | - | 310S | 310S |

| 12 | 0Crl7Nil2Mo2 | 06Crl7Nil2Mo2 | SUS316 | 316 | S31600 | STS316 | 1.4401 | 04Crl7Nil2Mo2 | 316 | 316 |

| 13 | 0Crl8Nil2Mo3Ti | 06Crl7Nil2Mo2Ti | SUS316TI | 316TI | S31635 | - | 1.4571 | 04Crl7Nil2MoTi20 | 316Ti | 316TI |

| 14 | 00Crl7Nil4Mo2 | 022Crl7Nil2Mo2 | SUS316L | 316L | S31603 | STS316L | 1.4404 | ~02Crl7Nil2Mo2 | 316L | 316L |

| 15 | 0Crl7Nil2Mo2N | 06Crl7Nil2Mo2N | SUS316N | 316N | S31651 | STS316N | - | - | 316N | 316N |

| 16 | 00Crl7Nil3Mo2N | 022Crl7Nil3Mo2N | SUS316LN | 316LN | S31653 | STS316LN | 1.4429 | - | 316LN | 316LN |

| 17 | 0Crl8Nil2Mo2Cu2 | 06Crl8Nil2Mo2Cu2 | SUS316J1 | - | - | STS316J1 | - | - | 316J1 | 316J1 |

| 18 | 00Crl8Nil4Mo2Cu2 | 022Crl8Nil4Mo2Cu2 | SUS316J1L | - | - | STS316J1L | - | - | - | 316J1L |

| 19 | 0Crl9Nil3Mo3 | 06Crl9Nil3Mo3 | SUS317 | 317 | S31700 | STS317 | - | - | 317 | 317 |

| 20 | 00Crl9Nil3Mo3 | 022Crl9Nil3Mo3 | SUS317L | 317L | S31703 | STS317L | 1.4438 | - | 317L | 317L |

| 21 | 0Crl8Nil0Ti | 06Crl8NillTi | SUS321 | 321 | S32100 | STS321 | 1.4541 | 04Crl8Nil0Ti20 | 321 | 321 |

| 22 | 0Crl8NillNb | 06Crl8NillNb | SUS347 | 347 | S34700 | STS347 | 1.455 | 04Crl8Nil0Nb40 | 347 | 347 |

| Austenitic-ferritic stainless steel (duplex stainless steel) | ||||||||||

| 23 | 0Cr26Ni5Mo2 | - | SUS329J1 | 329 | S32900 | STS329J1 | 1.4477 | - | 329J1 | 329J1 |

| 24 | 00Crl8Ni5Mo3Si2 | 022Crl9Ni5Mo3Si2N | SUS329J3L | - | S31803 | STS329J3L | 1.4462 | - | 329J3L | 329J3L |

| 0Crl8Nil0Ti ferritic stainless steel | ||||||||||

| 25 | 0Crl3AI | 06Crl3Al | SUS405 | 405 | S40500 | STS405 | 1.4002 | 04Crl3 | 405 | 405 |

| 26 | - | 022CrllTi | SUH409 | 409 | S40900 | STS409 | 1.4512 | - | 409L | 409L |

| 27 | 00Crl2 | 022Crl2 | SUS410L | - | - | STS410L | - | - | 410L | 410L |

| 28 | lCrl7 | 10Crl7 | SUS430 | 430 | S43000 | STS430 | 1.4016 | 05Crl7 | 430 | 430 |

| 29 | lCrl7Mo | 10Crl7Mo | SUS434 | 434 | S43400 | STS434 | 1.4113 | - | 434 | 434 |

| 30 | - | 022Crl8NbTi | - | - | S43940 | - | 1.4509 | - | 439 | 439 |

| 31 | 00Crl8Mo2 | 019Crl9Mo2NbTi | SUS444 | 444 | S44400 | STS444 | 1.4521 | - | 444 | 444 |

| Martensitic stainless steel | ||||||||||

| 32 | lCrl2 | 12Crl2 | SUS403 | 403 | S40300 | STS403 | - | - | 403 | 403 |

| 33 | lCrl3 | 12Crl3 | SUS410 | 410 | S41000 | STS410 | 1.4006 | 12Crl3 | 410 | 410 |

| 34 | 2Crl3 | 20Crl3 | SUS420J1 | 420 | S42000 | STS420J1 | 1.4021 | 20Crl3 | 420 | 420J1 |

| 35 | 3Crl3 | 30Crl3 | SUS420J2 | - | - | STS420J2 | 1.4028 | 30 Crl3 | 420J2 | 420J2 |

| 36 | 7Crl7 | 68Crl7 | SUS440A | 440A | S44002 | STS440A | - | - | 440A | 440A |

Which is better ss304 or ss316?

Since Type 316 stainless steel alloy contains molybdenum bearing it has a greater resistance to chemical attack than 304. Type 316 is durable, easy-to-fabricate, clean, weld and finish. It is considerably more resistant to solutions of sulfuric acid, chlorides, bromides, iodides and fatty acids at high temperature.

What is good quality stainless steel?

304 stainless steel is the most common form of stainless steel used around the world due to excellent corrosion resistance and value. 304 can withstand corrosion from most oxidizing acids. That durability makes 304 easy to sanitize, and therefore ideal for kitchen and food applications.

What is the difference between 304, 304H and 304L?

In fact, the content of chromium and nickel is 304 stainless steel, and the composition contains 18% chromium (Cr) and 8% nickel (Ni), but the main difference lies in the carbon content.

304L is an ultra-low carbon stainless steel. The carbon content is reduced to less than 0.03%, which can avoid intergranular corrosion. In theory, the effect of stress corrosion resistance is stronger than that of 304, but the effect is not obvious in practical applications. The purpose of reducing carbon and adding titanium is the same, but the smelting cost of titanium-added 321 is higher, the molten steel is thick, and the price is more expensive.

The H in 304H refers to high temperature. High carbon content is the guarantee of high temperature strength. GB150 requires that when austenitic steel is used above 525 degrees, the carbon content should not be less than 0.04%. Carbide is the strengthening phase, especially the high temperature strength. Better than pure austenite.

Among the three, the highest carbon content is 304H, the lowest carbon content is 304L, and the carbon content of 304 stainless steel is between the two. The higher the carbon content, the worse the corrosion resistance of stainless steel and the easier it is to rust. The difference in carbon content also causes the price to be different, or the requirements for different uses are also different.

Why is stainless steel so expensive?

Stainless steel is more expensive to produce because of the addition of the variety of alloying elements, such as iron, chromium, nickel, manganese and copper. … The chromium attaches itself to oxygen more readily than iron and thus creates a chromium oxide layer which protects the metal from degradation.

What is the safest stainless steel?

Stainless steel cookware is generally recognized as a safe material for cookware. Any good quality stainless steel, be it 304 or 316 stainless steel, is a better choice than most of the other available materials. For example, coated aluminum pans lose their non-stick over time.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed